Making your

Making your

Tom Biesot

Description associated with the tasks

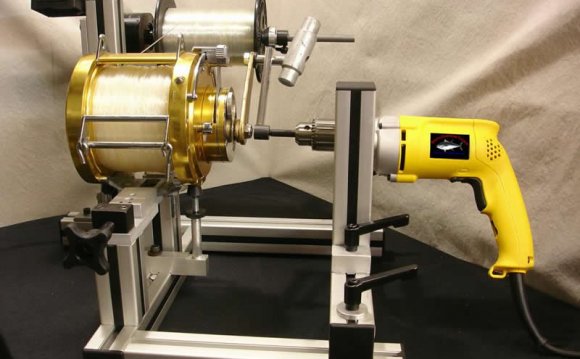

I will initially offer a quick information of project 1 with some images. It will be the more sophisticated one, that I made very first. Afterwards there may follow an even more extensive description including pictures of project 2: a simple but effective range winder which can be produced by most people in a straightforward method.

Design and choice of materials for task 1

I have chosen a wood design with classic appearance. We first made the technical drawings (task 1 design, project 1 detail), I quickly picked materials through the wood I had inside my disposal on my hobby loft. While I happened to be looking through the timber pile, I ran into some old Mahogany timber that my granddad had directed at myself a long time ago. Old, dried out and beautiful whole grain. Kind pieces because of this task. It believed particular unique to reduce them up all things considered these years.

Making the line winder

Making the line winder

For all important dimensions we make reference to the work design of task 2 here.

The entire setup is easy, a winding device by means of a disc, a reel seat, and some assistance obstructs. We very first turned a line winder disc to my tiny wood-turning lathe, from a huge piece of mahogany. After that we made some attractive holes when you look at the disc with the help of my stationary drill. It sort of gives the disc the look of a fly reel spool. I did not however result in the main gap to dimensions. This will be done at a later phase. (see images). For dimensions see Drawing for Project 2.

This will be done at a later phase. (see images). For dimensions see Drawing for Project 2.

Bottom plate and support blocks

These could be easily created from the massive mahogany board. Since I will always make-work drawings, it is not difficult to do, we simply stick to the dimensions and afterwards the edges would be finished with chamfers.

The help obstructs will likely then be drilled for screw holes in addition to holes the reel chair plus the straight support block a hole should be drilled when it comes to screw which will keep the bearing in position.

The help obstructs will likely then be drilled for screw holes in addition to holes the reel chair plus the straight support block a hole should be drilled when it comes to screw which will keep the bearing in position.

The reel seat

Because I went for classic looks I used mahogany for the reel chair as well (in task 2 i shall make use of a factory-made one). As I only have a tiny wood-turning lathe, the clamping rings plus the axle around which they move aren't hard to make. We glued an aluminium bushing inside movable clamp ring containing an internal screw-thread for a clamping screw.

Fixing the reel chair and rings

In addition milled a little amount area in the axle and glued a tiny aluminium dish about it therefore the clamping screw will not damage the wood. The bands have now been chamfered on the inside in order to collect the reel base easier. The fixed band has-been glued on the axle as well as the various other a person is movable, so we can clamp the reel. On both stops associated with the axle we shall spot a dowel (understand image). The reel seat is going to be glued between the clamping obstructs after which we will leave it for the moment.

RELATED VIDEO